10MM KUTI 130MM Kukanda Kukuya Media Simbi Bhora yeBhora Mill Metal Migodhi uye Simende Zvidyarwa

Chigadzirwa tsananguro

Nzira yekugadzira

Bhora rekukanda, rinodaidzwawo kuti bhora rekukanda, rinogadzirwa nesimbi yakaraswa, simbi yakaraswa, uye zvimwe zvinhu zvakaraswa.Izvo zvataurwa pamusoro apa zvakanyungudutswa zvakanyanya uye zvinoitisa inoenderera ikozvino mushure mekupisa.Munguva yekunyungudutsa, huwandu hukuru hwesimbi zvinhu zvakaita sevanadium, iron uye manganese zvinotanga kuwedzerwa kune flue gasi kuti uwane goho rinodiwa uye rakafanotemerwa.Zvinhu izvi zvinokwanisa kudurura simbi yakanyungudutswa mumhando yekugadzira simbi yekugadzira simbi.

Application

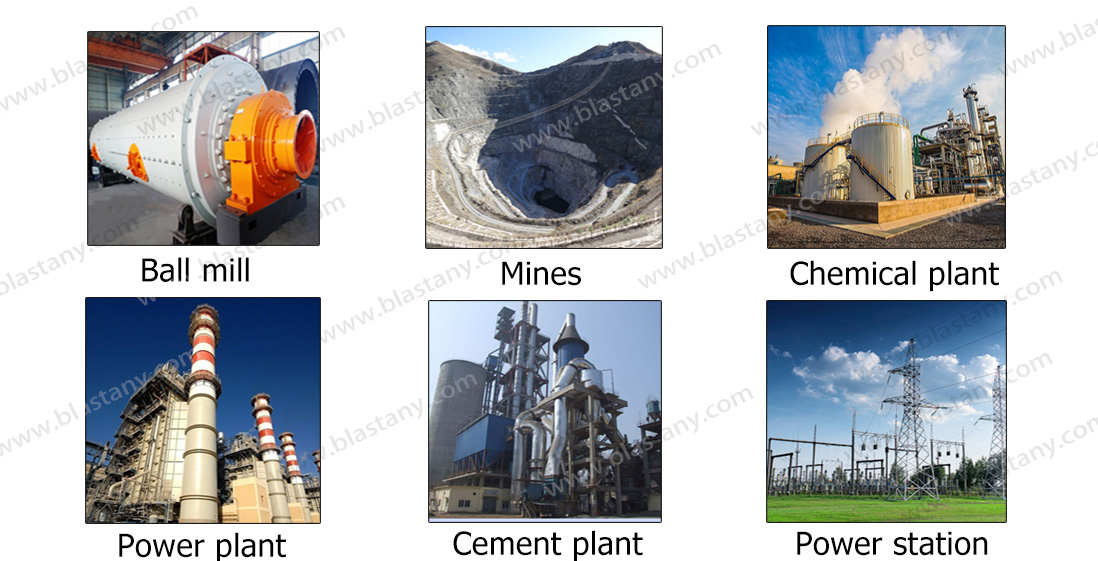

Kukandira Simbi Bhora inogona kunyanya kushandiswa mumashandisirwo akasiyana siyana, kusanganisira

Silica jecha fekitari/Simende chirimwa/Chemical chirimwa/Simba chirimwa/Migodhi/Simba zviteshi

/Chemical industries/Grinding mill/Ball mill/Coal mill

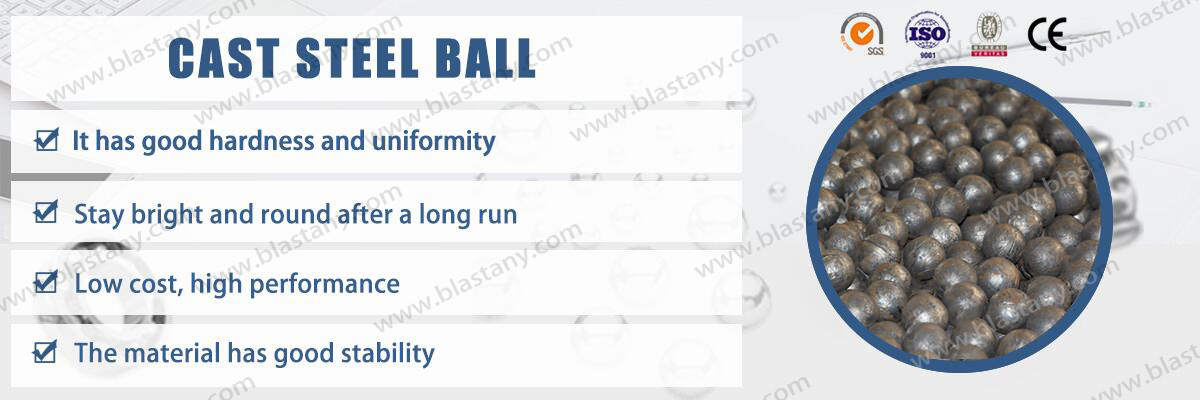

Nhanganyaya yekukanda simbi bhora zvigadzirwa

Chrome cast simbi mabhora ndiwo akakandwa anokuya midhiya mabhora ane imwe muzana yechromium, uye ayo akakamurwa kuita yakakwirira chromium cast simbi mabhora, epakati chromium akakanda simbi mabhora uye akaderera chromium akakanda simbi mabhora.Iwo chromium akakanda simbi mabhora akakamurwa kuita High Chromium Cast Steel Balls, Medium Chromium Cast Steel Balls uye Low Chromium Cast Steel Balls.Iine chimiro chekuomarara kwepamusoro, kupfeka kwakaderera, uye kuderera kwakadzika, mabhora esimbi ekukuya anonyanya kushandiswa muindasitiri yesimende, indasitiri yezvicherwa, indasitiri yesimbi, indasitiri yekugadzira magetsi uye indasitiri yekuvaka.

Kanda Kukuya Simbi Bhora Zvimiro

1, Zvigadzirwa zvese zvinotakura zvimedu zvesimbi, izvo zvine mhangura, molybdenum, nickel uye zvimwe zvakakosha simbi zvinhu, izvo zvinogona zvinobudirira kuvandudza matrix chimiro chesimbi bhora.

2, Zvigadzirwa zvedu zvinogadzirwa nepakati frequency electric furnace iyo inogona kunyatso chengetedza kugadzikana kwezvinhu.Mabhora haasi nyore kusvuura nekuremara panguva yekushandiswa.Kunyangwe inogona kuramba yakapenya uye yakatenderera mushure menguva yakareba ichimhanya.

3, Iyo yakanyanya kukwirisa hombe otomatiki yekudzima mafuta ekugadzira mutsara inogamuchirwa yekupisa kurapwa, iyo inovimbisa kunaka kuoma uye kufanana kwezvigadzirwa.

Nzira nhatu dzekugadzira mabhora esimbi

1. Nzira nhatu dzekugadzira bhora resimbi

Kune mhando nhatu dzesimbi bhora kugadzira maitiro: kukanda, kuforoma, nekukunguruka.

(1) Kukandira: Hunhu hwemabhora esimbi yakakandwa zvakanyanya zvinoenderana nezviri mukati mechromium.Mumakore achangopfuura, kukwira kwemutengo wechromium, kuchengetedzwa kwezvakatipoteredza, uye zvimwe zvinhu zvakakonzera kuwedzera kwemutengo wesimbi yakakandwa mabhora.

(2) Kugadzira: Kushandisa yakakwira manganese simbi seyakagadzirwa, sando dzekugadzira pneumatic uye molds dzebhora dzinoshandiswa kugadzira mabhora esimbi.Mabhora esimbi akaumbwa ane musanganiswa unonzwisisika wepamusoro-kabhoni, manganese, chromium, uye zvimwe zviwanikwa zvealloy, uye ane kuomarara kwakasimba mukugadzirwa kwekupisa kupisa, mutsauko mudiki mukuomarara pakati pemukati nekunze, uye mutsauko mukukosha kwekukanganisa, izvo zvinoita. mabhora aka forged akasimba kudarika mabhora ekukandwa.

(3) Kukunguruka: Uchishandisa masimbi akakwira manganese semidziyo, mabhora esimbi anogadzirwa ne skew rolling mill ine spiral rollers.

| Item | Muumbi weKemikari(%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

|

High chrome kanda mabhora egri nding | ZQCr12 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 11-13 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 |

| ZQCr15 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 14-17 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 | |

| ZQCr20 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 18-22 | ≤0.10 | ≤0.08 | 0-2.0 | 0-1.0 | 0-1.5 | |

| ZQCr26 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 22-28 | ≤0.10 | ≤0.08 | 0-2.5 | 0-2.0 | 0-1.5 | |

| Pakati chrome yakakanda bhora rekukuya ls | ZQCr7 | 2.0-3.2 | 0.3-1.5 | 0.2-1.0 | 6.0-10 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | 0-1.5 |

| Low chrome yakakanda mabhora ekukuya | ZQCr2 | 2.0-3.6 | 0.3-1.5 | 0.2-1.0 | 1.0-3.0 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | |

Yakakwira chromium yekukanda paramita (Yakakwira Chrome Bhora Parameter)

| Zita dhayamita | Huremu hwebhora rimwe muavhareji(g) | Huwandu/ MT | Kuoma kwepamusoro (HRC) | Endurance kukanganisa bvunzo (Nguva) |

| φ15 | 13.8 | 72549 |

>60 | >10000 |

| φ17 | 20.1 | 49838 | >10000 | |

| φ20 | 32.7 | 30607 | >10000 | |

| φ25 | 64 | 15671 | >10000 | |

| φ30 | 110 | 9069 | >10000 | |

| φ40 | 261 | 3826 | >10000 | |

| φ 50 | 510 | 1959 | >10000 | |

| φ60 | 882 | 1134 | >10000 | |

| φ70 | 1401 | 714 | >10000 | |

| φ80 | 2091 | 478 | >58 | >10000 |

| φ90 | 2977 | 336 | >10000 | |

| φ100 | 4084 | 245 | >8000 | |

| φ120 | 7057 | 142 | >8000 | |

| φ130 | 8740 | 115 | >8000 |

Zvigadzirwa zvikamu