Yemhando yepamusoro yakakandwa simbi yakapfurwa ine yakakwirira kupfeka kuramba

Introduce

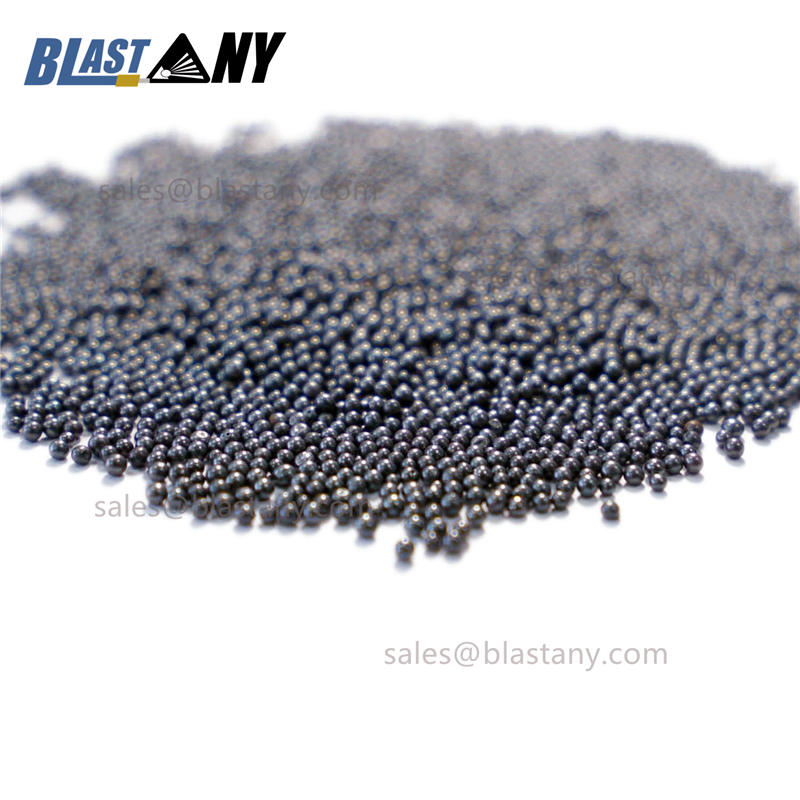

Junda Steel Shot inogadzirwa nekunyungudutsa zvimedu zvakasarudzwa muchoto chemagetsi induction. Iyo kemikari yemhando yesimbi yakanyungudutswa inoongororwa uye inodzorwa zvakanyanya ne spectrometer kuti uwane SAE Standard yakatarwa. Simbi yakanyungudutswa yakanyungudutswa inoshandurwa kuita atomi uye inoshandurwa kuita denderedzwa chidimbu uye yozodzimwa uye kudzikamiswa mukupisa kupisa kuti iwane chigadzirwa chekuomarara kweyunifomu uye microstructure, yakaongororwa nehukuru maererano neSAE Standard yakatarwa.

Junda indasitiri simbi pfuti yakakamurwa kuita ina, yenyika standard cast simbi pfuti, ine chromium cast simbi pfuti, mapiritsi epasi kabhoni simbi, simbi isina tsvina, kusanganisira yenyika standard cast simbi pfuti inopindirana zvizere nezvinodiwa nenyika zvinodiwa zvechinhu chemukati mukugadzirwa, uye chikamu chechromium chakakandwa simbi pfuti, chakavakirwa pachiyero chenyika chemabhora esimbi, kuwedzera ferromanganese senge ferrowen inonyungudika senge ferrowens kugadzirwa kwezvinhu zvinogara kwenguva refu. Yakaderera kabhoni simbi yekupfura kugadzirwa kwemaitiro uye yenyika standard simbi kupfura, asi iyo mbishi yakaderera kabhoni simbi, kabhoni yemukati yakaderera; Stainless simbi pfuti inogadzirwa neatomizing yekugadzira maitiro, mbishi simbi isina tsvina, 304, 430 simbi isina tsvina uye zvichingodaro.

Mhando yepfuti iyi inogadzirwa kuti ishandiswe mukupfurwa kwepfuti uye maitiro ekuputika pasi pekumanikidzwa nemhepo yakamanikidzwa. Inonyanya kushandiswa pane zvisiri zveferrous simbi sealuminium, zinc alloys, simbi isina tsvina, bhuronzi, ndarira, mhangura ...

Iine huwandu hwayo hwakakura hwemagiredhi, inoshandiswa kuchenesa, kubvisa, compaction, kupfurwa peening uye zvakajairika kupedzisa maitiro, pamhando dzese dzezvikamu, pasina kusvibisa nzvimbo yayo nemavhu ane ferrous ayo anoshatisa nekuchinja ruvara rwesimbi yakarapwa. kuitira kuchembera kwemarble negranite.

Industrial application

Simbi inoputika

Simbi yekupfura kuchenesa jecha rekukanda uye kupiswa -pajecha rekukanda kuita kuti nzvimbo yacho iwane kuchena kwakanaka uye inodiwa kushata, kuitira kuti inogona kubatsira kune kunotevera kugadzirisa uye kupfekedza.

Kanda simbi yekupfura yeSimbi plate yekugadzirira

Kanda simbi yekupfura kuchenesa ganda reoxide, ngura uye kumwe kusachena nepfuti Blasting, wozoshandisa vacuum cleaner kana mweya wakanatswa wakamanikidzwa kuchenesa zvigadzirwa zvesimbi.

Mapfuti esimbi anoshandiswa kuInjiniya muchina

Mapfuti eSimbi anoshandiswa kuchenesa Machina anogona kunyatsobvisa ngura, welding slag, uye oxide ganda, kubvisa kushushikana kwewelding, uye kuwedzera simba rekubatanidza pakati pekubvisa ngura nesimbi, nekudaro zvinosimudzira zvakanyanya kunaka kweinjiniya muchina spare part.

Simbi yekupfura saizi yeStainless simbi yekuchenesa ndiro

Kuti uwane kuchena, kupenya, nekunakisa kupisa kwepamusoro kurapwa kwesimbi isina tsvina, inofanirwa kusarudza iyo yakakodzera abrasive zvinhu kubvisa chiyero kubva kunotonhora yakakungurutswa simbi isina tsvina.

Zvinoenderana nemagiredhi akasiyana, iyo simbi isina tsvina yepasi inoda kusarudza akasiyana dhayamita mabrasives uye chikamu chekugadzirisa. Zvichienzaniswa nemaitiro emakemikari echinyakare, anogona kudzikisa mutengo wekuchenesa uye kuwana kugadzirwa kwegirinhi.

Simbi yakapfura inoputika media yePipeline anti-corrosion

Mapaipi esimbi anoda kurapwa kwepamusoro kuti asimbise kushora. Nekupfurwa kwesimbi, kuputika midhiya inokwenenzvera, kuchenesa uye kubvisa okisidhi uye zvakanamirwa zvinowana yakakumbirwa ngura kubvisa giredhi uye hudzamu hwezviyo, kwete chete kuchenesa nzvimbo asiwo kugutsa kunamira pakati pesimbi pombi uye coating, kuwana yakanaka anti-corrosion effect.

Steel shot peening kusimbisa

Zvikamu zvesimbi zvinoshanda mu cyclic kurodha mamiriro uye zvakaiswa kune chiitiko chebhasikoro kushushikana kunoda kupfurwa peening kusimbisa maitiro kuvandudza hupenyu hwekuneta.

Kanda simbi pfuti Application domains

simbi yekupfura peening inonyanya kushandiswa mukusimbisa kugadzirisa kwezvikamu zvakakosha senge helical chitubu, shizha chitubu, chakamonyoroka bhaa, giya, zvikamu zvekutapurirana, kutakura, cam shaft, akabhenda axle, tsvimbo yekubatanidza uye zvichingodaro. Kana ndege ichimhara, giya rekumhara rinofanirwa kumira nekutyisa kwarinoda kurapwa peening nguva nenguva. Iwo mapapiro anodawo iyo periodic stress kuburitsa kurapwa.

Technical Parameters

| Project | National Standards | Hunhu | |

| Kemikari yakagadzirwa% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Kuoma | simbi yakapfura | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Density | simbi yakapfura | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | Tempered Martensite kana Troostite | Tempered Martensite Bainite Composite sangano | |

| Chitarisiko | Spherical Hollow particles <10% Crack particle <15% | Spherical Hollow particles <5% Crack particle <10% | |

| Type | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Packing | Toni imwe neimwe muPallet yakaparadzana uye toni imwe neimwe yakakamurwa mu25KG mapaketi. | ||

| Kugara kwenguva refu | 2500 ~ 2800 nguva | ||

| Density | 7.4g/cm3 | ||

| Diameter | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Applications | 1. Kucheneswa kwekuputika: Inoshandiswa kuchenesa kuputika kwekukanda, kufa-casting, forging; jecha kubviswa kwekukanda, simbi ndiro, H mhando simbi, simbi chimiro. 2. Kubvisa ngura: Kubvisa ngura yekukanda, kuumba, ndiro yesimbi, H rudzi rwesimbi, chimiro chesimbi. 3. Shot peening: Shot peening yegiya, kupisa kwakarapwa zvikamu. 4. Shot blasting: Shot blasting of profile steel, ship board, simbi bhodhi, simbi zvinhu, simbi chimiro. 5. Pre-kurapwa: Pre-kurapwa kwepamusoro, simbi bhodhi, profile simbi, simbi chimiro, pamberi pekupenda kana kupfeka. | ||

Size Distribution Of Simbi Shot

| SAE J444 Standard Steel shot | Sikirini Nha. | In | Sikirini saizi | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| VOSE vanopfuura | 6 | 0.132 | 3.35 | |||||||||||

| All Pass | 7 | 0.111 | 2.8 | |||||||||||

| 90% min | All Pass | 8 | 0.0937 | 2.36 | ||||||||||

| 97% min | 85% min | All Pass | All Pass | 10 | 0.0787 | 2 | ||||||||

| 97% min | 85% min | 5% max | All Pass | 12 | 0.0661 | 1.7 | ||||||||

| 97% min | 85% min | 5% max | All Pass | 14 | 0.0555 | 1.4 | ||||||||

| 97% min | 85% min | 5% max | All Pass | 16 | 0.0469 | 1.18 | ||||||||

| 96% min | 85% min | 5% max | All Pass | 18 | 0.0394 | 1 | ||||||||

| 96% min | 85% min | 10% max | All Pass | 20 | 0.0331 | 0.85 | ||||||||

| 96% min | 85% min | 10% max | 25 | 0.028 | 0.71 | |||||||||

| 96% min | 85% min | All Pass | 30 | 0.023 | 0.6 | |||||||||

| 97% min | 10% max | 35 | 0.0197 | 0.5 | ||||||||||

| 85% min | All Pass | 40 | 0.0165 | 0.425 | ||||||||||

| 97% min | 10% max | 45 | 0.0138 | 0.355 | ||||||||||

| 85% min | 50 | 0.0117 | 0.3 | |||||||||||

| 90% min | 85% min | 80 | 0.007 | 0.18 | ||||||||||

| 90% min | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Matanho ekugadzira

Raw material

Kuumba

Kuomesa

Kuongorora

Selection

Tempering

Kuongorora

Package

Zvigadzirwa zvikamu