Girazi mabhedhi anoratidza hukuru "hushamwari hwepamusoro" zvichienzaniswa nemamwe akawanda abrasives, akadai sealumina, silicon carbide, uye simbi grit. Hunhu uhwu hunonyanya kukonzerwa nekusiyana kwayo kwemuviri nemakemikari. Iyo yepamusoro-hushamwari hwemagirazi mabhedhi inoratidzwa mukukwanisa kuchenesa kana kupuruzira nzvimbo zvakanaka uchideredza kukuvadzwa kwechikamu chebasa pachacho.

Izvi zvinotevera zvinhu zvakati wandei zvinokonzeresa chiitiko ichi:

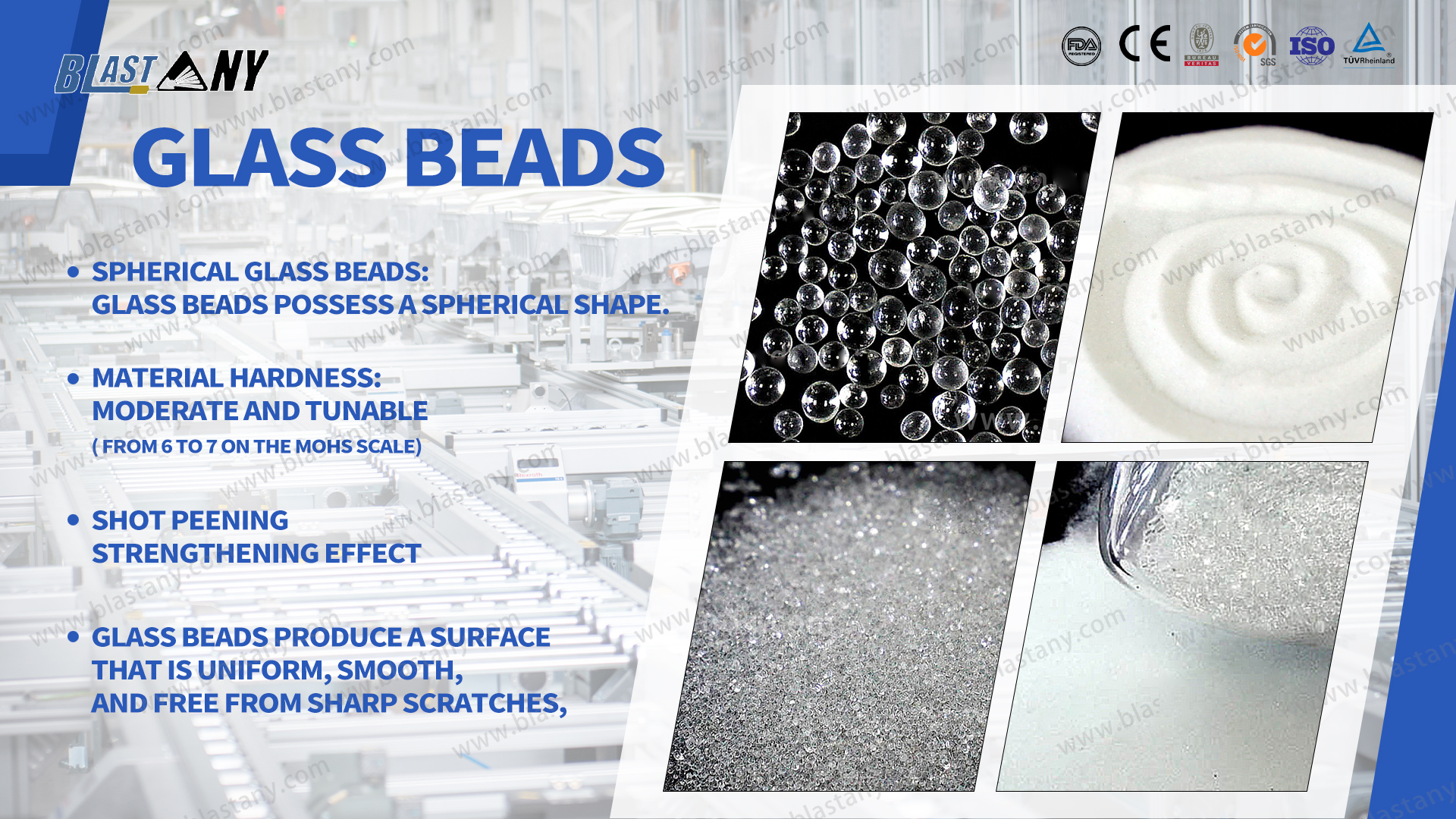

1.Shape uye Chimiro: Spherical vs. Angular

- Spherical Glass Beads: Magirazi egirazi ane chimiro chakatenderera. Munguva yekugadzira jecha pane workpiece nzvimbo, ivo vanogadzira point contacts. Iyi yekubata modhi inokonzeresa kushomeka kwekushushikana. Chiito chacho chakanyanya kufanana ne "tapping" kana "kukungurutsa" mhedzisiro, kunyanya kushanda kubvisa hutachiona hwepamusoro, senge ngura machira uye mafirimu ependi ekare, pasina kudzika mukati meiyo workpiece zvinhu.

-Angular Abrasives: Mukupesana, mabrasives sebrown corundum, simbi grit, uye mhangura slag anowanzo kuratidza akapinza uye asina kujairika mipendero. Kana ichishandiswa kugadzira jecha, vanoita mutsara kana mapoinzi ekubatanidza, zvichiunza kushushikana kwakanyanya kwenzvimbo. Izvi zvinofananidzwa netudiki tudiki tudiki tunoveza pamusoro.

Iyo spherical chimiro chegirazi mabhedhi zvinobudirira kudzivirira kucheka uye gomba kunokonzerwa neakapinza mipendero, nekudaro ichideredza zvakanyanya kupfeka kweworkpiece uye kuderedza kuwedzera kwekushata kwepamusoro.

2.Material Hardness: Pakati nepakati uye Tunable

Kuoma kwegirazi mabhero kunowanzo kubva pa6 kusvika ku7 pachiyero cheMohs. Iyi nhanho yekuomarara inokwana kubvisa zvinokanganisa zvakajairika, senge ngura (ine Mohs kuomarara kwe4 - 5) uye mafirimu ependi ekare. Panguva imwe chete, inenge yakaderera kudarika kana kuenzaniswa nekuoma kwezvinhu zvakawanda zvesimbi.

3. Shot Peening Kusimbisa Mhedzisiro

The spherical impact yegirazi beads panzvimbo dzesimbi inoburitsa yunifomu uye miniti compressive stress layer. Ichi chinyorwa chinopa zvikomborero zvakawanda:

- Kuwedzera Kuneta Resistance: Inovandudza kuneta kwesimba resimbi zvikamu, zvinobudirira kuramba kutangwa uye kupararira kwekutsemuka.

- Yakaderedzwa Stress Corrosion Risk: Iyo compressive stress layer inodzikisira mukana wekushushikana corrosion.

- Yakavandudzwa Wear Resistance: Nekukwevera kushoma kutonhora kuoma pamusoro pepamusoro, inosimudzira kupfeka kuramba kwezvinhu.

4. Pamusoro Pedzisa

Nekuda kwechimiro chadzo chakatenderera uye maitiro ekuita, magirazi mabhero anoburitsa nzvimbo yakafanana, yakatsetseka, uye isina makwara akapinza, anowanzo kunzi "satin kupera". Kupedzisa uku kunopa yakanakira substrate yekuzotevera kupfapfaidza, kukoira, kana electroplating maitiro, kuve nechokwadi chekunamatira kwakasimba kwekunamatira.

Sezvineiwo, angular abrasives inogadzira yakakasharara pamusoro petopography ine nhongonya uye mipata. Nepo izvi zvichigonawo kuwedzera kunamira kune imwe nhanho, zvinodya zvakawanda zvekupfekedza zvinhu uye zvinokonzeresa kutaridzika kusingafadze kwepamusoro.

Tichifunga nezvezvakanakira izvi, magirazi mabheji anowanzo shandiswa mumashandisirwo uko kutendeseka kweiyo substrate kwakakosha zvakanyanya, sekugadziriswa kweiyo chaiyo zvikamu, molds, aerospace components, Stainless simbi zvigadzirwa, uye aluminium alloy die-castings. Vanomiririra sarudzo yakakwana yekuwana chiyero pakati pekuchenesa kwepamusoro kwepamusoro uye kuchengetedzwa kwe substrate.

Kuti uwane rumwe ruzivo, ndapota inzwa wakasununguka kukurukura nekambani yedu!

Nguva yekutumira: Sep-18-2025