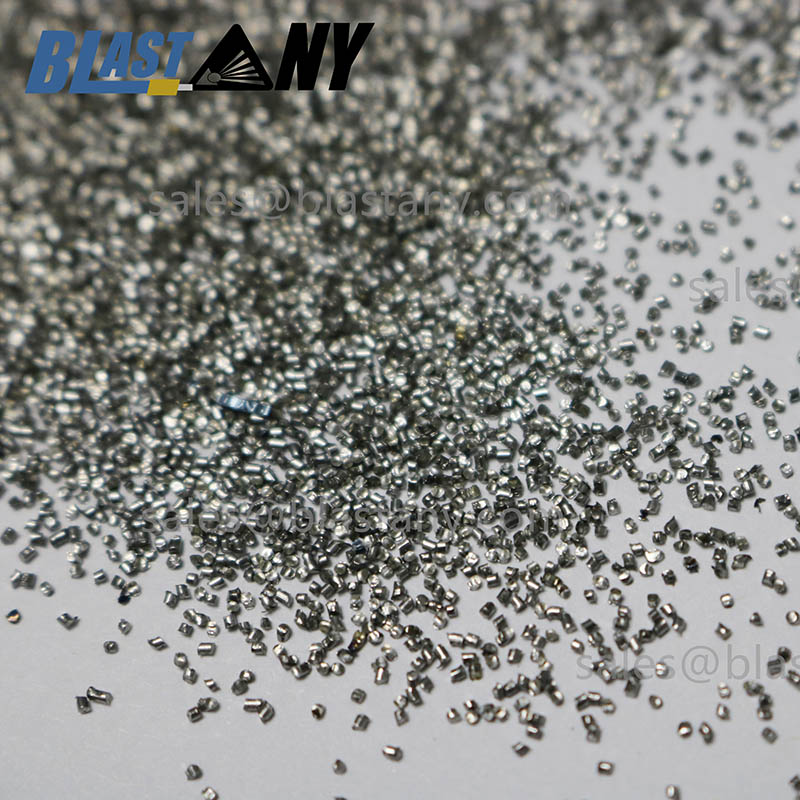

Stainless simbi yakapfurwa ine atomization kugadzira tekinoroji

Munda Wekushandisa

1.Kupedzwa kwepamusoro kwealuminium zinc kufa kukanda uye kuchenesa pamusoro pearuminiyamu jecha kukanda. artificial marble surface spraying and polishing. Kuchenesa uye kupedzisa kweakakwira alloy simbi yekukanda pamusoro oxide chiyero, aluminium alloy injini block uye zvimwe zvakakura zvekukanda zvikamu, marble pamusoro pekuita kurapwa uye antiskid kurapwa.

2.Aluminium zinc die casting, kucheneswa kwepamusoro kwekukandwa kwechokwadi, kukwiza kwepamusoro pamberi pekupfekedzwa kwakakosha, kukwenenzverwa kwekupfapfaidza kwealuminium profiles kubvisa mitsara yekubvisa pamusoro, kunatswa kupfapfaidza kwemhangura aruminiyamu pombi pamusoro, uye kunatswa kupfapfaidza kwesimbi isina simbi nevharuvhu.

3. Chenesa maturusi ekukanda anotonhora, chromium plating inofa yekugadzira mafi nematayi, gadziridza chivharo chepombi chemotokari injini supercharger, simbisa iyo chaiyo giya uye chitubu chemutangi, uye pfapfaidza kupukuta pamusoro pesimbi isina tsvina.

4.Aluminium zinc die casting, mudhudhudhu injini bhokisi, silinda musoro, carburetor, injini yemafuta pombi goko, pombi yekudya, kukiya mota. Pamusoro peiyo low pressure die casting vhiri mbiri ichacheneswa uye kupedzwa usati wapenda. Kupedzwa kwepamusoro uye kucheneswa kwemhangura aluminium simbi isina stamping zvikamu, mari yekukanda simbi isina tsvina, nezvimwe.

Technical Parameters

| Project | 304 Hunhu | 430 Hunhu | |

| Kemikari yakagadzirwa% | C | 0.08-1.0 | <0.2 |

| Si | 0.4-1.2 | <1.5 | |

| Mn | 0.35-1.2 | 0.8-1.2 | |

| S | <0.05 | <0.05 | |

| P | <0.05 | <0.05 | |

| Cr | 15-16.5 | 15-17 | |

| Ni | 5-8% | 0 | |

| Kuoma | HRC40-50 | HRC35-50 | |

| Density | 7.00 g/cm3 | ||

| Microstructure | austenitic | Ferrite | |

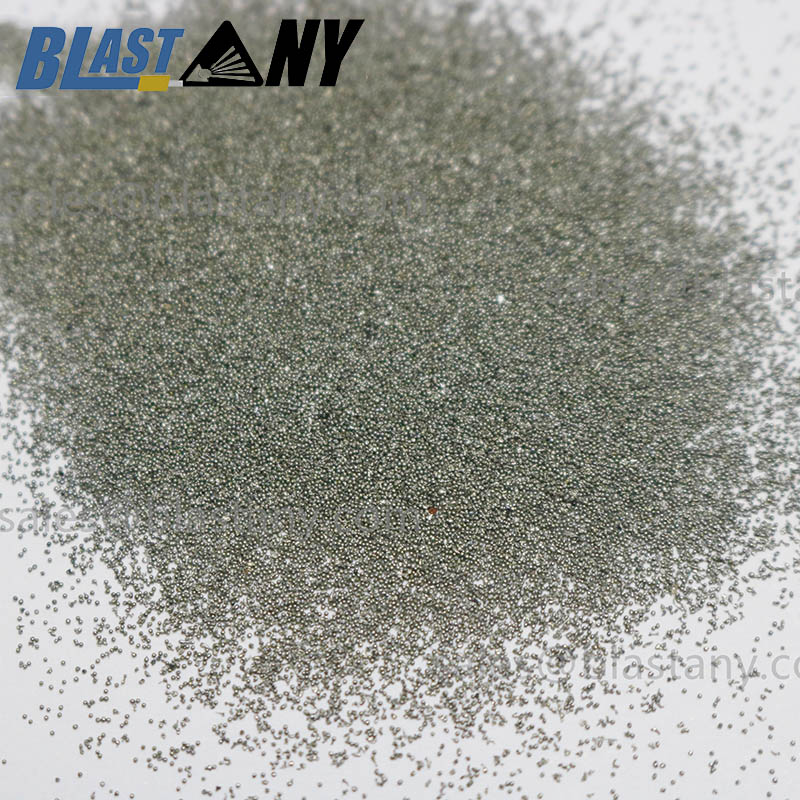

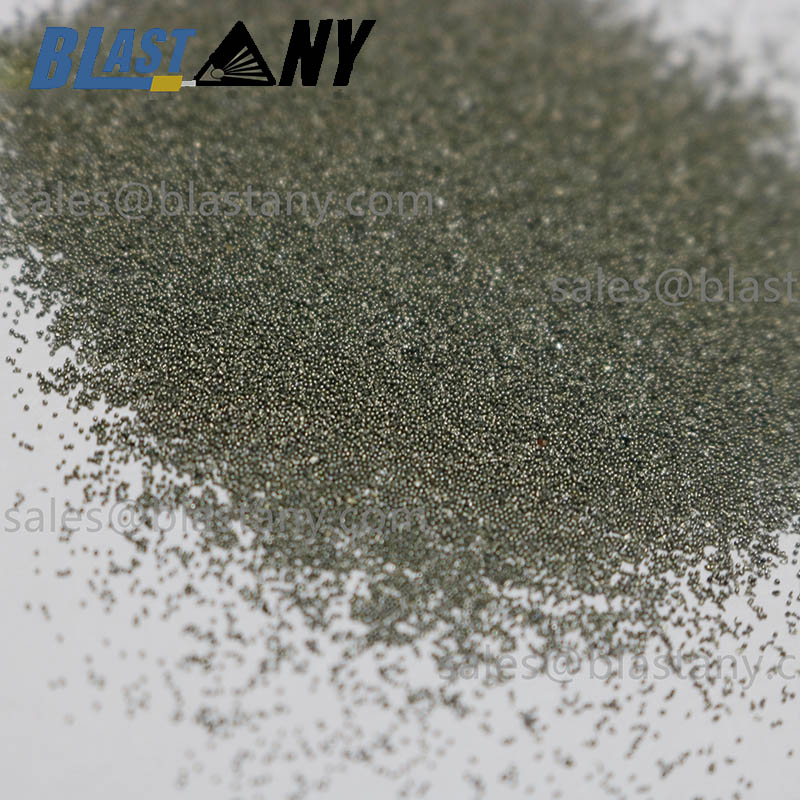

| Chitarisiko | Spherical Hollow particles=0% Hollow particles=0% | ||

| Type | 14-18# / 16-20# / 20-25# / 25-30# / 30-40# / 40-70# / 70-140# / 140-270# | ||

| Packing | Toni imwe neimwe muPallet yakaparadzana uye toni imwe neimwe yakakamurwa mu25KG mapaketi. | ||

| Kugara kwenguva refu | 27000 ~ 28000 nguva | ||

| Density | 7.0g/cm3 | ||

| Application | Inonyanya kushandiswa kubvisa uye kupera kwepamusoro kwealuminium kufa kukandira, zinc alloy die casting uye magnesium alloy die casting; kupedzwa kwepamusoro kwekukandira kwakanyatso, kukanda simbi isina tsvina uye landscape block; kugadzira magirazi, kucheneswa kwepamusoro uye kwakasiyana-siyana pretreatment yefa yekukanda mold. | ||

Application

| TYPE | Inokurudzirwa chiyero chekushandisa |

| 14-18# | Chenesa maturusi ekukanda anotonhora, chromium plating inofa yekugadzira matai, gadziridza chivharo chepombi chemotokari injini supercharger, simbisa iyo chaiyo giya uye chitubu chekutanga, uye kupfapfaidza kupukuta pamusoro pesimbi isina tsvina. |

| 16-20# | Aluminium zinc die casting, kucheneswa kwepamusoro kwekukandwa kwechokwadi, kukwiza kwepamusoro pamberi pekupfekedzwa kwakakosha, kukwenenzverwa kwekupfapfaidza kwealuminium profiles kubvisa mitsara yekubvisa pamusoro, kunatswa kupfapfaidza kwemhangura aruminiyamu pombi pamusoro, uye kunatswa kupfapfaidza kwesimbi isina simbi nevharuvhu. |

| 20-25# | Aluminium zinc die casting, mudhudhudhu injini bhokisi, silinda musoro, carburetor, injini yemafuta pombi goko, pombi yekudya, kukiya mota. Pamusoro peiyo low pressure die casting vhiri mbiri ichacheneswa uye kupedzwa usati wapenda. Kupedzwa kwepamusoro uye kucheneswa kwemhangura aluminium simbi isina stamping zvikamu, mari yekukanda simbi isina tsvina, nezvimwe. |

| 25-30# | Aluminium zinc die casting surface finishing, aluminium jecha rinokanda pamusoro pekuchenesa. Kumusoro kwemarble ekugadzira kunopfapfaidzwa nekukwenenzverwa. |

| 30-40# | Kuwedzera kune wg40 basa, pamusoro pekukanda simbi isina tsvina yakatsetseka uye yakanaka. Descaling kurapwa kwesimbi alloy forgings. Artificial marble surface finishing effect uye antiskid treatment. |

| 40-70# | Yakakwira alloy simbi inokanda pamusoro oxide ganda, aluminium alloy injini block uye mamwe makuru ekufa ekukanda zvikamu kuchenesa uye kupedzisa, marble pamusoro pekuita kurapa uye anti-skid kurapwa. |

| 70-140# 140-270# | Iyo yepamusoro yekukandwa kwesimbi yakadhindwa isati yapfekedzwa, mota vhiri hub, injini ganda rekurapa, zvigadzirwa zvegranite uye nhanho dzemarble roughening uye anti-skid kurapwa. |

Granularity

| ScreenNO. | Screen size mm | In | 14-18 | 16-20 | 20-25 | 25-30 | 30-40 | 40-70 | 70-140 | 140-270 |

| 14 | 1.4 | 0.0555 |

|

|

|

|

|

|

|

|

| 16 | 1.18 | 0.0469 |

|

|

|

|

|

|

|

|

| 18 | 1 | 0.0394 |

|

|

|

|

|

|

|

|

| 20 | 0.85 | 0.0331 |

|

|

|

|

|

|

|

|

| 25 | 0.71 | 0.0278 |

|

|

|

|

|

|

|

|

| 30 | 0.6 | 0.0234 |

|

|

|

|

|

|

|

|

| 35 | 0.5 | 0.0197 |

|

|

|

|

|

|

|

|

| 40 | 0.425 | 0.0165 |

|

|

|

|

|

|

|

|

| 50 | 0.3 | 0.0117 |

|

|

|

|

|

|

|

|

| 70 | 0.212 | 0.0083 |

|

|

|

|

|

|

|

|

| 100 | 0.15 | 0.0059 |

|

|

|

|

|

|

|

|

| 140 | 0.106 | 0.0041 |

|

|

|

|

|

|

|

|

| 270 | <0.05 | <0.0019 |

|

|

|

|

|

|

|

|

Zvigadzirwa zvikamu