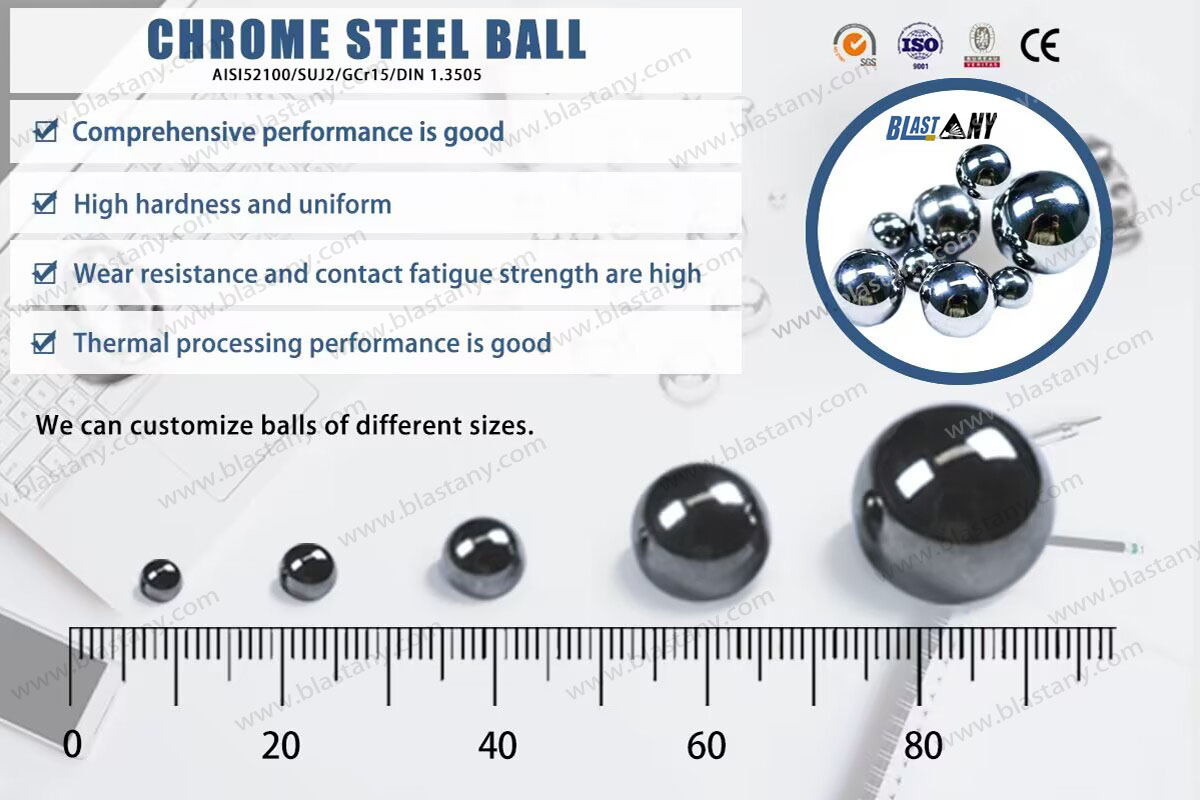

Yepamusoro Hunhu AISI52100 GCr15 4mm G10-G1000 Chrome Simbi Bhora reMudhudhudhu / Zvikamu zveBhasikoro/ Kutakura Bhora

Chigadzirwa tsananguro

Nekuda kwehunhu hwayo hwakadai sekuoma kukuru, kusamira kwepamusoro, kupera kwakanaka kwepasi uye kushivirira kwakadzika, iyo yakaderera-alloy martensitic AISI 52100 chromium simbi inoshandiswa pakugadzira mabearings nemavharuvhu.

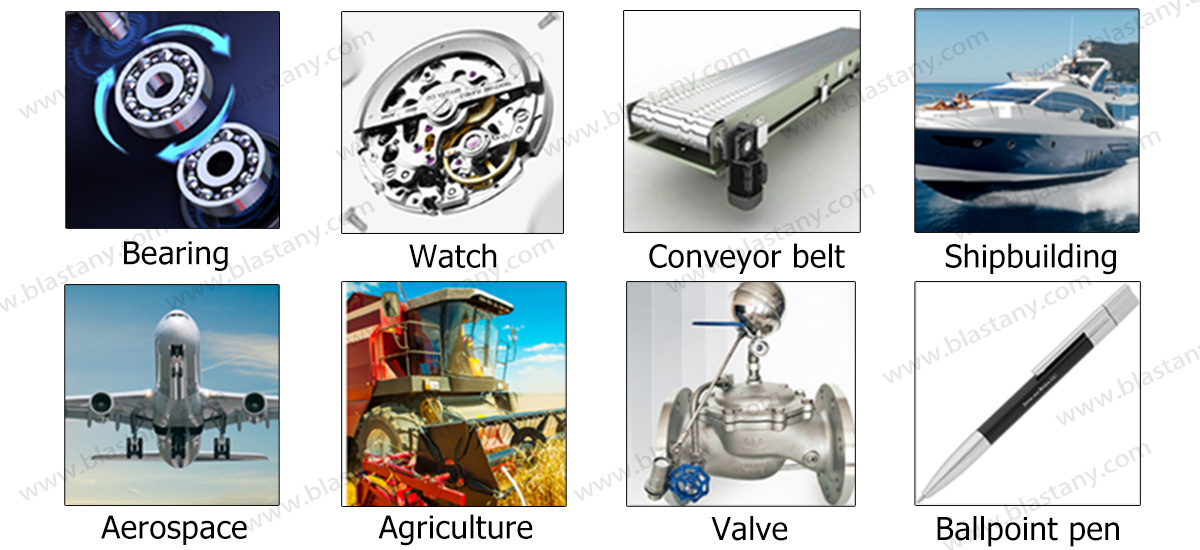

Nzvimbo dzekushandisa

Mabhora anotenderedza, mavharuvhu, mabhanhire anokurumidza, mabheji ebhora, zvinhu zvemotokari (mabhureki, chidhiraivho, kutapurirana), mabhasikoro, magaba eerosol, madhirowa madhiraivha, maturusi emuchina, makiyi, mabhandi ekutakurisa, bhutsu, zvinyoreso, pombi, mavhiri anotenderera, zviridzwa zvekuyeresa, bhora remagetsi masiruuru.

parameter list

| Chrome Simbi Bhora | |

| Material | AISI52100/SUJ2/GCr15/DIN 1.3505 |

| Size Range | 0.8mm-50.8mm |

| Giredhi | G10-G1000 |

| Kuoma | HRC:60~66 |

| Features | (1) Kushanda kwakakwana kwakanaka. (2)kuoma kwepamusoro uye yunifomu. (3)Kupfeka kuramba uye kubata kuneta simba kwakakwira. (4) Thermal processing performance yakanaka. |

| Application | Chrome inotakura bhora rinonyanya kushandiswa kugadzira mabhora esimbi, rollers uye bushings pamadhiraivha emoto senge injini dzinopisa mukati, magetsi emagetsi, maturusi emuchina, matirakita, midziyo yekutenderedza, zvidhinha zvekuchera, mota dzenjanji nemichina yemigodhi. |

| Kemikari yakagadzirwa | ||||||

| 52100 | C | Si | Mn | P | S | Cr |

| 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 0-0.025 | 0-0.020 | 1.40-1.65 | |

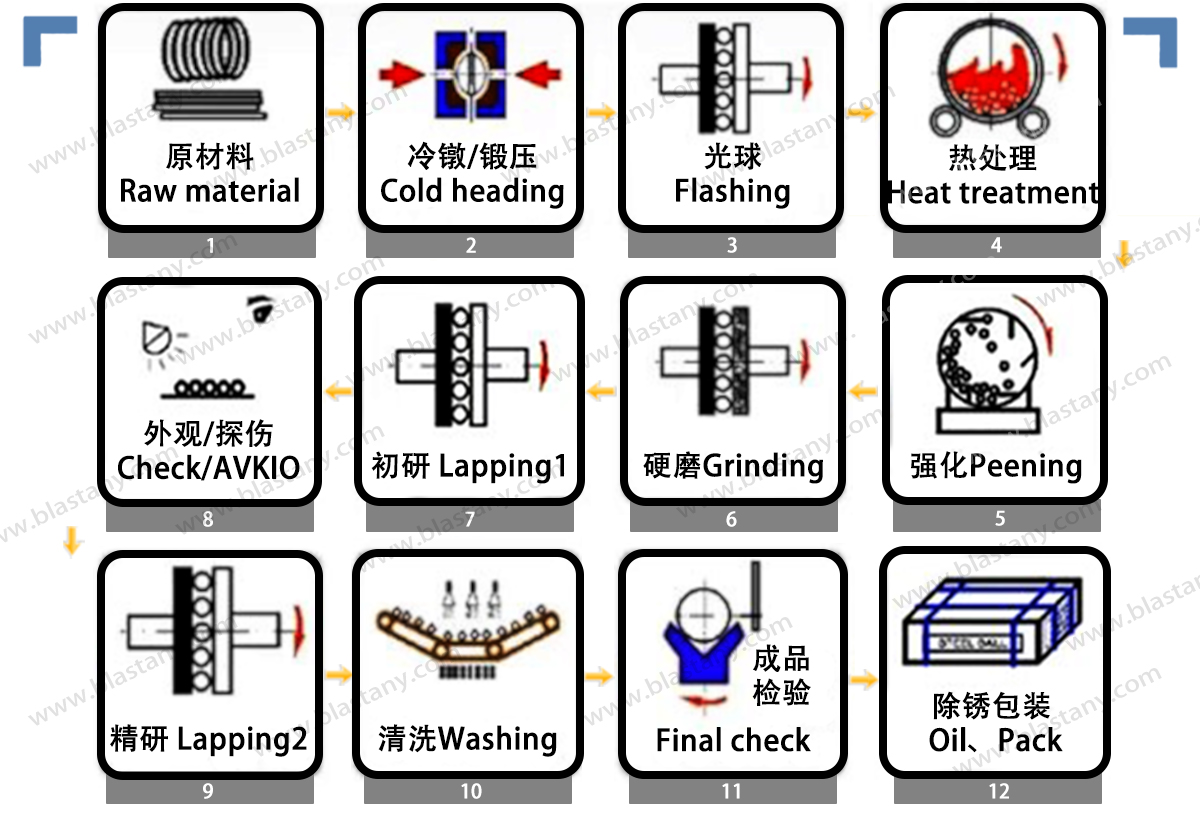

Nzira yekugadzira

Raw Material Inspection

Raw material inouya nenzira yewaya. Chekutanga, iyo mbishi inotariswa zvinoonekwa nevatarisi vemhando kuti vaone kana mhando iri kumusoro uye kana paine zvinhu zvakakanganisika. Chechipiri, simbisa dhayamita uye ongorora zvitupa zvezvinhu zvakasvibirira.

Cold Heading

Muchina wemusoro unotonhora unocheka kureba kwakatarwa kwewaya kuita cylindrical slugs. Mushure meizvozvo, mahafu maviri ehemispherical emusoro anofa anoumba slug kuita denderedzwa. Iyi nzira yekugadzira inoitwa pakamuri tembiricha uye zvishoma zvekuwedzera zvinhu zvinoshandiswa kuve nechokwadi chekuti mhango yekufa yakazadzwa zvachose. Cold heading inoitwa nekumhanya kwakanyanya, neavhareji yevelocity yebhora hombe pasekondi. Mabhora madiki anotungamirwa nekumhanya kwemabhora maviri kusvika mana pasekondi.

Kupenya

Munguva iyi, izvo zvakawandisa zvakaumbwa zvakatenderedza bhora zvichabviswa. Mabhora anopfuudzwa kaviri pakati pemahwendefa maviri esimbi akachekwa achibvisa hushoma hwezvinhu zvakawandisa paanenge achikunguruka.

Kupisa Kurapa

Izvo zvikamu zvinofanirwa kuve zvinopisa kupisa uchishandisa quenching uye tempering process.A rotary furnace inoshandiswa kuve nechokwadi chekuti zvikamu zvese zvinotakura mamiriro akafanana. Mushure mekutanga kupisa kupisa, zvikamu zvinonyudzwa mumudziyo wemafuta. Uku kutonhora nekukurumidza (kudzima mafuta) kunoburitsa martensite, chikamu chesimbi chinoratidzwa nekuomarara kwepamusoro uye hukuru hwekupfeka zvivakwa. Mavhiya anozotevera ekudzikisira anowedzera kudzikisira kushushikana kwemukati kudzamara mabearings ekupedzisira ekuomarara asvika.

Kukuya

Kukuya kunoitwa zvose zvisati zvaitika uye mushure mekupisa kupisa. Pedzisa Kukuya (kunozivikanwawo seKugaya Kwakaoma) kunounza bhora padyo nezvinodiwa zvekupedzisira.Chiyero chebhora resimbi chairochiyero chekururama kwayo kwese; iyo yakaderera nhamba, iyo inonyanya kujeka ibhora. Bhora giredhi rinotenderedza dhayamita kushivirira, kutenderera (sphericity) uye kushata kwepamusoro kunonziwo kupera kwepamusoro. Precision kugadzira bhora ibasa rebatch. Saizi yeroti inotarwa nehukuru hwemuchina unoshandiswa pakukuya nekupeta.

Lapping

Lapping yakafanana nekugaya asi ine mwero wakaderera wekubvisa zvinhu. Lapping inoitwa uchishandisa maviri phenolic plates uye akanyanya abrasive slurry senge guruva redhaimani. Iyi yekupedzisira nzira yekugadzira inovandudza zvakanyanya kushata kwepamusoro. Lapping inoitwa nekuda kwepamusoro-chaiyo kana super-chaiyo bhora mamakisi.

Kuchenesa

Basa rekuchenesa rinobva rabvisa chero zvinwiwa zvekugadzirisa uye zvakasara zveabrasive zvinhu kubva mukugadzira maitiro. Vatengi vanokumbira zvimwe zvakaomesesa zvekuchenesa zvinodiwa, senge izvo zviri muminda yemicroelectronics, zvekurapa kana maindasitiri ezvekudya, vanogona kutora mukana weHartford Technologies yakanyanya kuoma yekuchenesa sarudzo.

Visual Inspection

Mushure mekutanga kugadzira maitiro, yega yega mabhora esimbi echokwadi anoenda akawanda mu-process quality control checks. Ongororo yekuona inoitwa kuti itarise zvirema zvakaita se ngura kana tsvina.

Roller Gauging

Roller gauging i100% yekuronga maitiro inoparadzanisa ese ari pasi-saizi uye pamusoro-saizi chaiyo mabhora esimbi. Ndokumbira utarise yedu yakasiyanavhidhiyo pane roller gauging process.

Quality Control

Mabhora ega ega ega ega anoongororwa kuti ive nechokwadi chegiredhi inodiwa kushivirira, kutenderera uye kushata kwepamusoro. Munguva iyi, mamwe maitiro akakodzera akadai sekuoma, uye chero zvinoonekwa zvinodiwa zvinoongororwawo.

Zvigadzirwa zvikamu