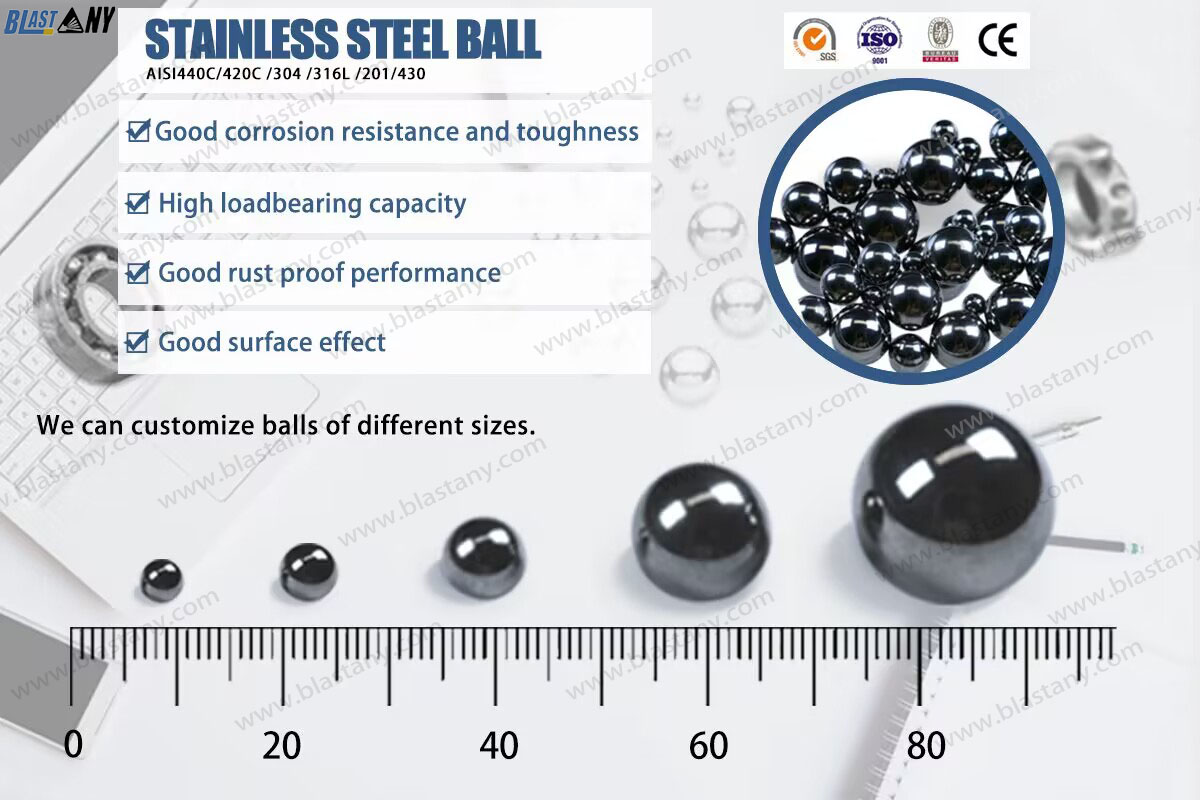

Fekitari inopa 0.35mm- 50.8mm HRC50-55 mwenje AISI304 316 430 440 Stainless simbi bhora Inoshandiswa muBearing

Chigadzirwa tsananguro

Mabhora asina tsvina anokwanisa kuramba kuodzwa nemaajenti akadai seoxidizing mhinduro, mazhinji organic makemikari, chikafu zvinhu uye sterilizing mhinduro. Izvo zvine mwero kusagadzikana kune sulfuric acids. Non-magnetic zvivakwa zviripo pakukumbira. Zvikumbiro zvinosanganisira aerosol, sprayers, zvigunwe pombi michina, mukaka muchina mablender, chikafu chekugadzira chikafu uye mishonga yekurapa.

AISI 440C Stainless simbi bhora

Kukura: 0.35mm-50.8mm

Giredhi: G10, G16, G40, G60, G100, G200.

Kuoma: HRC56-58, Hartford 440C Stainless simbi mabhora anopfuudzwa kuti abvise mahara esimbi zvinosvibisa uye kufambisa kungoerekana kuumbwa kweinodzivirira passive firimu.

Magnetic: Martensitic simbi, magineti

Zvimiro: kurongeka kwepamusoro, kumira kwakanaka kwecorrosion, ngura yakasimba uye kusagadzika kwekupfeka.

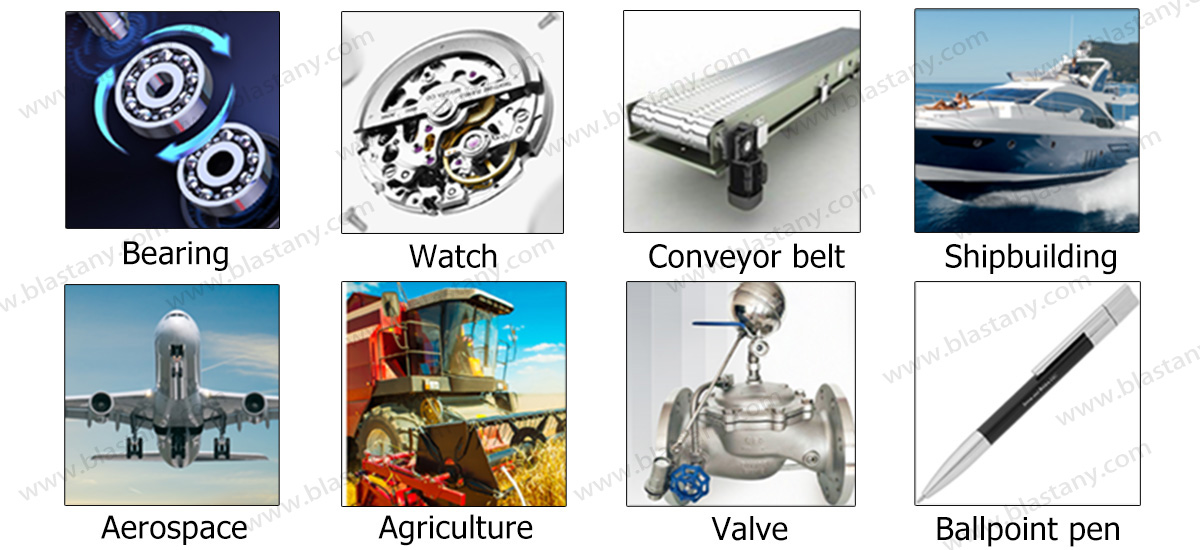

Zvishandiso: Bearings, stamping, hydraulic parts, mavharuvhu, aerospace, zvisimbiso, firiji midziyo, yakakwirira-chaiyo zviridzwa, etc.

| Kemikari yakagadzirwa | ||||||||

| AISI 440C | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.95-1.10 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.60 | 16.0-18.0 | 0.75 | |

AISI 420C Stainless simbi bhora

Kukura: 0.35mm-50.8mm

Giredhi: G10-G1000

Kuoma: HRC50-55

Magnetic: Martensitic simbi, magineti, Yakanaka anti-ngura kugona, kuomarara kwepamusoro, AISI 420 mabhora esimbi asina tsvina anoratidza kunaka kwekupfeka uye kuoma. Zvishoma zvishoma kuomarara uye kusimba kukuru kwegora, kana ichienzaniswa ne440C.

Zvimiro: Inowanzozivikanwa sesimbi isina tsvina, yakanaka corrosion kuramba uye kuoma.

Zvishandiso: Ese marudzi emakina chaiwo, mabheji, midziyo yemagetsi, midziyo yemumba, zvikamu zvemotokari, nezvimwe.

| AISI 420C(4Cr13) | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.36-0.43 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.60 | 12.0-14.0 | ≤0.60 |

430 Stainless simbi bhora

Dhayamita: 1MM-50.80MM

Kuoma: HRC26

Giredhi: G10-G1000

Zvimiro: mutengo wakaderera, kushomeka kwemarara.

Application:hardware, ornaments, accessories, cosmetics, industry, maindasitiri ane zvakaderera zvinodiwa kuti antirust performance.Cosmetics agitators, nail polish and eyeliners, heat exchangers, measurement instruments. uye mabhora evharuvhu.

| AISI 430 | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | - | 16.0-18.0 | - |

AISI 304 Stainless simbi bhora

Kukura: 0.5mm- 63.5mm

Giredhi: G80-G500

Kuoma: ≤HRC21

Magnetic:Austenitic simbi, isiri-magnetic

Zvimiro: yakasimba rust resistance, good corrosion resistance.widely used, good rust proof performance, good surface effect, chitupa chekuchengetedzwa kwezvakatipoteredza.

Zvishandiso: Zvishandiso zvemumba zvakaita semavharuvhu, mabhodhoro epefume, polish yezvipikiri, mabhodhoro evana, auto parts, air conditioners, midziyo yemagetsi, cosmetics, kutakura siraidhi, mishonga yekurapa, zvishongo nemamwe maindasitiri mazhinji.

| Kemikari yakagadzirwa | |||||||

| AISI 304 | C | Si | Mn | P | S | Ni | Cr |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-22.0 | |

AISI 316L Stainless simbi bhora

Saizi: 1.0mm-63.5mm

Giredhi: G80-G500

Kuoma: ≤HRC26

Magnetic:Austenitic simbi, isiri-magnetic

Zvimiro: iyo yakanyanya kufanirwa maindasitiri ane yakakwira anti-corrosion zvinodiwa, uye anti-ngura kugona kwakasimba, Yakanakisa kupikisa mukuora (kunze kwechloridric acids), Haisi yakaoma austenitic inox.

Zvishandiso: AISI 316L Stainless simbi bhora inogona kushandiswa pamidziyo yekurapa, indasitiri yemakemikari, avhiyesheni, aerospace, epurasitiki hardware, pefiyumu bhodhoro, sprayer, mavharuvhu, chipikiri polish, mota, switch, iron, washing machines, firiji, air conditioners, mishonga, auto parts, bearings, instrument, bhodhoro.

AISI 316L Stainless simbi bhora

| Kemikari yakagadzirwa | ||||||||

| AISI 316L | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | |

Product Packaging

A) Kurongedza kwemukati: Dry packing kana mafuta kurongedza zvinopihwa zvinoenderana nezvaunoda.

B) Kurongedza kwekunze:

1) dhiramu resimbi + danda / simbi pallet.

2) 25kg poly bag + katoni + mapuranga pallet kana bhokisi remapuranga.

customized kurongedza.

Product Parameter

| Yedu Stainless Simbi Bhora inosanganisira 440C 420C 304 316 201, Iyo Chemical kuumbwa kuri kunotevera. | |||||||||

| Kemikari yakagadzirwa (%) | C | Cr | Si | Mn | P | S | Mo | Ni | Cu |

| AISI440C SS Bhora | 0.95-1.2 | 16-18 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.75 | ≤0.6 | ---- |

| AISI420C SS Bhora | 0.26-0.43 | 12-14 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.6 | ≤0.6 | ---- |

| AISI304 SS Bhora | ≤0.08 | 18-22 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | ---- | 8-10 | ---- |

| AISI316L SS Bhora | ≤0.08 | 16-18 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 2.0-3.0 | 12-15 | ---- |

| AISI201 SS Bhora | ≤0.15 | 16-18 | ≤1.0 | 5.5-7.5 | ≤0.045 | ≤0.03 | ---- | 0.35-0.55 | 1.82 |

| AISI430 SS Bhora | ≤0.12 | 16-18 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ---- | ---- | ---- |

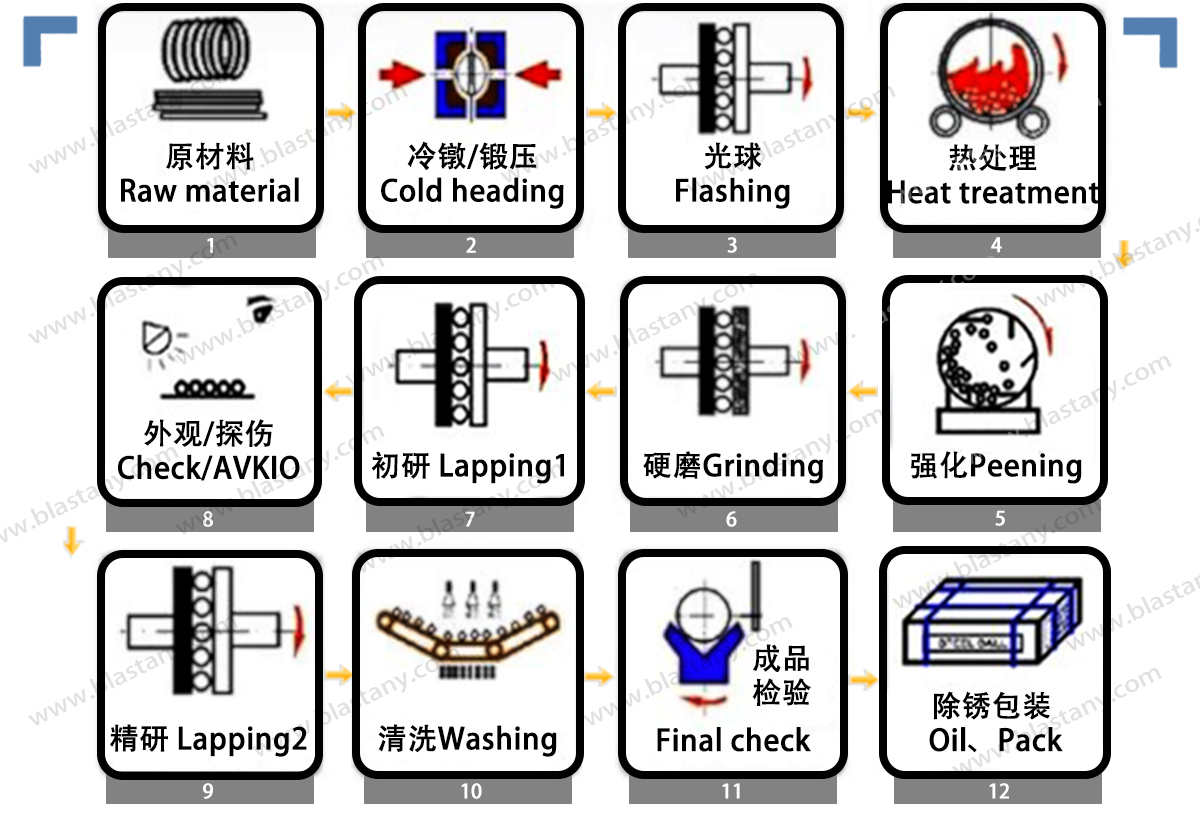

Kugadzirwa Kunoyerera

Raw Material Inspection

Raw material inouya nenzira yewaya. Chekutanga, iyo mbishi inotariswa zvinoonekwa nevatarisi vemhando kuti vaone kana mhando iri kumusoro uye kana paine zvinhu zvakakanganisika. Chechipiri, simbisa dhayamita uye ongorora zvitupa zvezvinhu zvakasvibirira.

Cold Heading

Muchina wemusoro unotonhora unocheka kureba kwakatarwa kwewaya kuita cylindrical slugs. Mushure meizvozvo, mahafu maviri ehemispherical emusoro anofa anoumba slug kuita denderedzwa. Iyi nzira yekugadzira inoitwa pakamuri tembiricha uye zvishoma zvekuwedzera zvinhu zvinoshandiswa kuve nechokwadi chekuti mhango yekufa yakazadzwa zvachose. Cold heading inoitwa nekumhanya kwakanyanya, neavhareji yevelocity yebhora hombe pasekondi. Mabhora madiki anotungamirwa nekumhanya kwemabhora maviri kusvika mana pasekondi.

Kupenya

Munguva iyi, izvo zvakawandisa zvakaumbwa zvakatenderedza bhora zvichabviswa. Mabhora anopfuudzwa kaviri pakati pemahwendefa maviri esimbi akachekwa achibvisa hushoma hwezvinhu zvakawandisa paanenge achikunguruka.

Kupisa Kurapa

Izvo zvikamu zvinofanirwa kuve zvinopisa kupisa uchishandisa quenching uye tempering process.A rotary furnace inoshandiswa kuve nechokwadi chekuti zvikamu zvese zvinotakura mamiriro akafanana. Mushure mekutanga kupisa kupisa, zvikamu zvinonyudzwa mumudziyo wemafuta. Uku kutonhora nekukurumidza (kudzima mafuta) kunoburitsa martensite, chikamu chesimbi chinoratidzwa nekuomarara kwepamusoro uye hukuru hwekupfeka zvivakwa. Mavhiya anozotevera ekudzikisira anowedzera kudzikisira kushushikana kwemukati kudzamara mabearings ekupedzisira ekuomarara asvika.

Kukuya

Kukuya kunoitwa zvose zvisati zvaitika uye mushure mekupisa kupisa. Pedzisa Kukuya (kunozivikanwawo seKugaya Kwakaoma) kunounza bhora padyo nezvinodiwa zvekupedzisira.Chiyero chebhora resimbi chairochiyero chekururama kwayo kwese; iyo yakaderera nhamba, iyo inonyanya kujeka ibhora. Bhora giredhi rinotenderedza dhayamita kushivirira, kutenderera (sphericity) uye kushata kwepamusoro kunonziwo kupera kwepamusoro. Precision kugadzira bhora ibasa rebatch. Saizi yeroti inotarwa nehukuru hwemuchina unoshandiswa pakukuya nekupeta.

Lapping

Lapping yakafanana nekugaya asi ine mwero wakaderera wekubvisa zvinhu. Lapping inoitwa uchishandisa maviri phenolic plates uye akanyanya abrasive slurry senge guruva redhaimani. Iyi yekupedzisira nzira yekugadzira inovandudza zvakanyanya kushata kwepamusoro. Lapping inoitwa nekuda kwepamusoro-chaiyo kana super-chaiyo bhora mamakisi.

Kuchenesa

Basa rekuchenesa rinobva rabvisa chero zvinwiwa zvekugadzirisa uye zvakasara zveabrasive zvinhu kubva mukugadzira maitiro. Vatengi vanokumbira zvimwe zvakaomesesa zvekuchenesa zvinodiwa, senge izvo zviri muminda yemicroelectronics, zvekurapa kana maindasitiri ezvekudya, vanogona kutora mukana weHartford Technologies yakanyanya kuoma yekuchenesa sarudzo.

Visual Inspection

Mushure mekutanga kugadzira maitiro, yega yega mabhora esimbi echokwadi anoenda akawanda mu-process quality control checks. Ongororo yekuona inoitwa kuti itarise zvirema zvakaita se ngura kana tsvina.

Roller Gauging

Roller gauging i100% yekuronga maitiro inoparadzanisa ese ari pasi-saizi uye pamusoro-saizi chaiyo mabhora esimbi. Ndokumbira utarise yedu yakasiyanavhidhiyo pane roller gauging process.

Quality Control

Mabhora ega ega ega ega anoongororwa kuti ive nechokwadi chegiredhi inodiwa kushivirira, kutenderera uye kushata kwepamusoro. Munguva iyi, mamwe maitiro akakodzera akadai sekuoma, uye chero zvinoonekwa zvinodiwa zvinoongororwawo.

Zvigadzirwa zvikamu